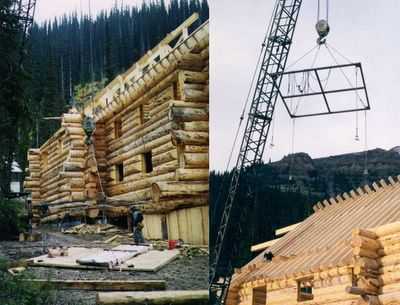

Roof Construction for Vertebrae Lodge

The two wings of Vertebrae Lodge have very different roof designs. Roof support in the bedroom wing is distributed between the walls of central hallways. The cathedral ceiling of the main roof is supported by a truss system with central posts. The span is large and the roof loads are very heavy. The Chatter team could deal with the bedroom roof, but the truss design for the main roof required outside help.

Christoph Loesch of Parson and his associates Sigi Liebmann of Golden and Zsolt Mozes of Parson visited Chatter Creek over a weekend and, between them and the Chatter Team, three large trusses were designed, constructed and erected into place.

Scroll down to view the progress of the roof construction. Click on photos to enlarge them and use the browser's "Back" button to return.